Satisfaction for the Global Environment

Via resource recycling initiatives that use limited resources and energy without wasting them, we will take on climate change and other challenges confronting a sustainable society, and strive to create a resilient society that preserves the beautiful global environment.

Materiality

- Engaging with climate change issues via corporate activities

- Developing goods, services and mechanisms to encourage the recycling of resources

- Investigating and reducing hazardous chemical substances

The PLUS Group Environmental Philosophy and Policy

Related SDGs

Highlights in 2024

Percentage of environmentally-friendly products in catalog 78%*

We have actively worked on developing environmentally-friendly furniture products, stationery products, and meeting tools in “PLUS Catalog 2024.”

* SKU calculation

Material Reverse System More than 99% recycled

We have achieved a recycling rate of over 99% using “MRS,” a total recycling system for used office furniture.

Managing 17.5ha of green space in order to conserve biodiversity

PLUSLAND is an industrial complex that maintains an appropriate balance in symbiosis between nature and humans, and has created a rich natural environment.

-

Highlights in 2023

Excellent Energy- PLUSLAND Forest Saving Business S Rank Certification Four years in a row

We have been awarded the S Rank Certification in an evaluation system divided by business class by the Agency for Natural Resources and Energy, Energy Conservation Subcommittee.

MRS recycle rate 99%

We have realized an MRS recycle rate of 99% or more.

PLUSLAND Forest Tree-planting initiative with over 30,000 trees of 58 varieties

PLUSLAND is a composite manufacturing facility that maintains an appropriate balance in symbiosis between nature and humans, and has created a rich natural environment.

Individual thoughts on Satisfaction for the Global Environment

Engaging with climate change issues via corporate activities

Environmental Philosophy/ Environmental Policy of the PLUS Group

We engage in a variety of environmental conservation activities while understanding the environmental impact of our business, based on the PLUS Group Environmental Philosophy and Environmental Policy.

Environmental Philosophy

Realization of socially optimality system

PLUS CORPORATION omits the unnecessary duplication from raw material procurement to manufacturing, sales, use, disposal, collection and recycling based on the corporate philosophy "Unique Values - Higher Satisfaction." stated in PLUS no kokoro.

PLUS contributes to the sustainable development of a recycling-oriented economic society in which resources and energy are effectively utilized without waste by discovering and creating "social optimality system" which reconstructs businesses in a rational and simple manner.

- Product Development

As a manufacturer, we strive to develop unique, ecological and user-friendly products which create a new value for consumer. - Distribution Development

From a social point of view beyond the scope of a company, we work on reconstruction of the business structure to improve efficiency of distribution by sharing functional capabilities in distribution network.

Environmental Policy

We put our Environmental Philosophy into action according to the following principle.

- We consider the environmental impact of our business activities, products and services, and strive to prevent pollution.

- We develop unique environmentally friendly products and services that create new value.

- We promote environmental conservation activities in all areas of our business activities.

- We reduce the environmental load by eliminating any overlapping operation.

- We comply with all relevant environmental laws and regulations, and requirements agreed upon by each department.

- We will grasp the environmental impact of our business practices, set environmental objectives and targets for improvement, operate plans, review them, and strive for continuous improvement of our environmental management system.

- We strive to conserve energy and resources as well as to reduce and recycle waste in our business practices.

- We seek to raise awareness of environmental conservation among employees through environmental education.

- We share this environmental policy with all employees working in PLUS and people working with PLUS, and make it accessible to the general public.

Conceptual Life Cycle Diagram

Engaging with climate change issues via corporate activities

Recognizing that measures against climate change are an important challenge in the creation of a sustainable society, the entire Group will endeavor to gain a grasp of the volume of greenhouse gas emissions generated through all business activities, including procurement, manufacturing, sales, and delivery, and strive to reduce them.

-

Calculate greenhouse gas (GHG) emissions and set reduction targets

Under the “The PLUS Group Environmental Philosophy and Environmental Policy”, we are tackling various activities for conserving the environment while ascertaining the effects our business activities have on the environment and making efforts for a recycling-based society.

Environmental Performance Data

Reporting period: FY2024 (2024.1.1-2024.12.31)

Guidelines: Ministry of the Environment "Environmental Reporting Guidelines FY2018"/ ISO 26000- Reporting period for Pentel Co., Ltd., Pentel Chemical Co., Ltd., Orient Enterprise Co., Ltd., and 22 overseas group companies of Pentel: FY2024 (April 1, 2023 – March 31, 2024)

Reportable organizations:

Covered Entities Scope 1 Scope 2 Scope 3 PLUS CORPORATION Including Maebashi Plant, Yorii Plant, Tokorozawa Plant, and Osaka Plant ● ● ● Some of the

headquarters and plants

of consolidated subsidiariesPLUS VIETNAM INDUSTRIAL CO., LTD. (Dong Nai Province, Vietnam) ● ● ● PLUS Stationery Shanghai Co., Ltd. (Shanghai City, China) ● ● ● Shantou PLUS Instruments Co., Ltd. (Shantou City, China) ● ● ● Nippon Notebook Corporation Nippon Notebook Corp. Okayama Plant ● ● ● Nippon Notebook Vietnam Co., Ltd ● ● ● THE SAILOR PEN CO., LTD. ● ● ● PENTEL CO., LTD. ● ● ● Pentel Chemical Corporation ● ● ORIENT ENTERPRISE Co., Ltd. ● ● 22 overseas group companies of PENTEL CO., LTD ● ● Independent third-party assurance report

Environmental Performance Data for reportable organizations has been verified by a third party (Sustainability Accounting Co., Ltd.) for the reliability of information disclosure.

Independent third-party assurance report

click on the thumbnail to enlarge

click on the thumbnail to enlargeBreakdown of GHG emissions by category in FY2024

Scope Category Scope/Category name Emissions intensity

(t-CO2)Ratio by

Scope (%)Scope 3

ratio (%)1 - Direct emissions 3,916 0.7 - 2 - Indirect emissions from energy sources 28,173 4.7 - 3 1 Purchased goods and services 393,018 94.6 69.0 2 Capital goods 8,481 1.5 3 Fuel- and energy-related activities not included in Scope 1 and 2 3,820 0.7 4 Upstream transportation and distribution 18,266 3.2 5 Waste generated in operations 741 0.1 6 Business travel 626 0.1 7 Employee commuting 2,111 0.4 8 Upstream leased assets - - 9 Downstream transportation and distribution - - 10 Processing of sold products - - 11 Use of sold products 92,258 16.2 12 End-of-life treatment of sold products 49,361 8.7 13 Downstream leased assets 830 0.1 14 Franchises - - 15 Investments - - Scope 1 and 2 total 32,089 5.4 Scope 3 total 569,512 94.6 Total 601,601 100.0 100.0 - Scope 2 is based on the market-based approach

-

Engage in initiatives to reduce CO2 emissions

Initiatives to reduce CO2 emissions from our businesses and plants

With the aim of achieving a low-carbon society, we implement energy-saving action in locations such as our offices and plants, as well as other initiatives against global warning.

Action Location Content of the initiative Installation of solar panels Maebashi Plant In November 2013, we established the PLUS Maebashi Plant Power Plant. It has a power generation output of 500 kW. The annual power generation in fiscal year 2024 was 526,614 kWh (83.2%*1 compared to the previous fiscal year), and the annual CO2 emission reduction was 227t*2. All the generated power is sold to TEPCO. - *1

Decreased due to a malfunction of power conditioners that convert electricity during certain periods.

*2Calculation based on the TEPCO CO2 emission coefficient (0.000390t-CO2/kWh) submitted to the website of the Ministry of the Environment Government of Japan in fiscal 2024.

Yorii Plant We have installed solar panels on the roof of the facility where we are tenanted. There are instruments that display the daily amounts of power generated and power used, and the sunlight intensity, and energy-saving measures are thoroughly enforced. PLUS Stationery Shanghai Co., Ltd In 2023, we installed solar panels at the plants of PLUS Stationery Shanghai Co., Ltd. Reuse of Waste Heat Maebashi Plant We effectively use the exhaust heat from the large dust collector in the factory. The warm air discharged during product processing is purified and circulated for air conditioning (heating) in the factory. Yorii Plant Effective use is made of waste heat from compressors. In the summer, warm air is released to the outside through ducts in the plant to adjust the air conditioning (cooling) inside, and in the winter, it is circulated indoors (for heating). The Top Light System Maebashi Plant We installed large lighting windows in key areas of the plant ceiling. The top light system utilizes openings in the ceiling, and can be expected to let in three times more light than windows installed in walls. It is particularly effective for large buildings such as plants where light from wall openings does not penetrate as far as the central areas. PLUS VIETNAM INDUSTRIAL CO., LTD. The height of LED tube lights at the Nhon Trach Plant was lowered from 4 m to 2.5 m, thereby reducing the number of lights while maintaining the same level of lighting. The reduction in the annual electricity consumption in fiscal year 2024 was 3,627 kWh, with a 2.3 t-CO2 reduction in CO2 emissions. Use of Roof Insulation Maebashi Plant Covering a section of the roof with insulation makes the building less affected by external heat and cold, reducing the consumption of energy to run heating and cooling equipment, such as electricity, gas and oil. Installation of Electric Energy Meters PLUS VIETNAM INDUSTRIAL CO., LTD We are working to reduce power consumption by changing from fluorescent and high voltage lights to LED lights in the plant and improving the efficiency of energy use at existing manufacturing facilities. In order to measure the effectiveness of these measures, electricity consumption is being monitored by watt-hour meters installed in each electrical box. Application of Insulation PLUS VIETNAM INDUSTRIAL CO., LTD Electricity consumption and CO2 emissions were successfully reduced by applying insulation to the T-dies*3 of inflation molding machines and heavy extruders, and to the screw sections of the injection molding machines.*4 Similar measures were implemented during fiscal year 2024 for the screw parts of molding machines for paper file binders, leading to a reduction in the annual electricity consumption of 7,280 kWh and CO₂ emissions of 5.5 tons. - *3

Molds used for film production

- *4

Machine that molds thermally melted plastic by pouring it into a mold

SHANTOU PLUS INSTRUMENTS CO.,LTD. The installation of insulation materials to exhaust pipes of air compressors and dryers, screw parts of injection molding machines, mechanical covers and exhaust pipes of shrink wrapping machines*5, heating parts of bag sealing machines, and IR heating parts*6 and exhaust pipes of UV printing machines*7 has led to a reduction in electricity consumption and CO₂ emissions. - *5

Machines that wrap products in heat-shrink film.

- *6

Parts that heat up with the use of infrared rays (IR).

- *7

Printing machines that use ultraviolet (UV) light for instantly curing and drying ink.

Application of Inverter PLUS VIETNAM INDUSTRIAL CO., LTD New inverters*8 were installed during fiscal year 2024 for ventilation fans at the pad printing*9 section that were constantly running at high speed to limit downtime electricity consumption, thereby leading to a reduction in annual electricity consumption of 3,215 kWh and CO₂ emissions of 2.2 t-CO₂. - *8

Devices for accurately controlling motor rotation.

- *9

A printing method in which silicon rubber pads containing ink are pressed, like a stamp, onto products.

Installation of automated timers PLUS VIETNAM INDUSTRIAL CO., LTD. The installation of a timer device that automatically stops the distribution of water during breaks in the scissor manufacturing process helped to prevent the water distribution system from operating continuously, resulting in a reduction in annual electricity consumption of 24,837 kWh and CO₂ emissions of 16.9 t-CO₂ in fiscal year 2024. Light-Down Campaign PLUS CORPORATION

Group companies in JapanFollowing on from the “CO2 Reduction/Light-Down Campaign” launched by the Ministry of the Environment, Government of Japan in 2003, we are intensifying our PLUS Light-Down Campaign. We are implementing it in tandem with work style reforms and have set a target that “all employees leave work and switch off the office lights by 19:00.” On July 12, 2023, we urged employees at 24 locations, including our Headquarters, Toranomon Office to leave work by 7 PM, and turn off all the lights. Plus/Minus One Degree Campaign PLUS CORPORATION

Some Group companies in JapanAs an energy-saving initiative in our offices, we implemented our Plus/Minus One Degree Campaign where the office temperature setting is moved by one degree centigrade. During the summer months from June to September 2023, the standard temperature setting was changed from 25℃ to 26℃, and in the winter months from November 2023 to March 2024 it was changed from 26℃ to 25℃. Reducing CO2 emissions via reductions in plastic raw materials

We are striving to reduce CO2 emissions via reduced use of plastic raw materials. PLUS VIETNAM INDUSTRIAL CO., LTD. is our production hub of stationery products. At the Bien Hoa Plant, plastic resin offcuts generated during product molding are put into a crusher with a robot arm and recycled for use as raw materials, and the Nhon Trach Plant has taken steps to reduce the amount of plastic resin wasted when changing polypropylene sheet rolls.

Amount of recycled plastic used

Of the 9,410t of plastic used at the Nhon Trach Plant and the 1,477t used at the Bien Hoa Plant, roughly 1,185t is recycled for use

-

Biodiversity Conservation

Biodiversity Conservation

Developing goods, services and mechanisms to encourage the recycling of resources

In order to make efficient use of limited resources, we promote resource-saving design and reuse waste materials such as offcuts and used products to reduce the amount of raw materials utilized and waste generated, while also promoting the creation of products with a view to recycling. We carry out in-depth research from the perspectives of materials, design and recycling technology, and propose new systems and services.

-

Galvanize initiatives aimed at a circular economy

-

Promote a total recycling system for used office furniture

-

Develop environmentally friendly products

Environmentally-friendly products that aim to reduce CO2 emissions and reduce the use of plastics

The PLUS Group is making proactive efforts in environmentally-friendly products with the aim to realize a sustainable society. In the “PLUS Catalog 2024,” 78% of furniture products, stationery products and meeting tools were environmentally friendly products.

Release of Third Lineup of “COE365” Series

PLUS Corporation released six products in 2024 in its third lineup of the “COE365 series” eco-friendly stationery brand catering to Gen Z students, providing them with an environmentally friendly approach to having fun while considering the future. The series is a new range of environmentally friendly products made to help reduce the use of plastics, with a package-free design and recycled resin used for the main bodies.

“MOKURAL” Project Entry Model “Vicenda ramo”

The “Vicenda” series of timber-metal composite office furniture made from domestic fast-growing broad-leaved bead trees was released in 2023 under “MOKURAL,” which is a project that aims to revitalize the health of forests and achieve carbon neutrality through the proactive use of domestic timber. The cost-effective “Vicenda ramo” entry model was released in January 2025. The lineup comprises three products—tables (double- and single-sided types) and stools—with the core material made of domestically sourced cedar and surface made of melamine resin, in a style that blends eco-friendly design with strength. The “Vicenda” series also features a new single-sided type and café tables made of fast-growing broad-leaved bead trees. We will continue revitalizing both people and forests by coming up with proposals for office spaces that bring nature even closer.

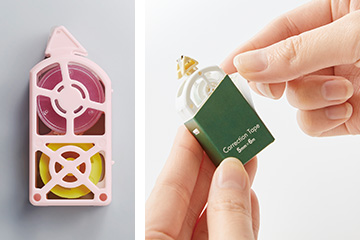

Eco-friendly “Roller Kes’pon Slim Fit” Privacy Protection Stamp made with Paper Materials

The new eco-friendly “Roller Kes’pon Slim Fit” privacy protection stamp made with paper materials was released in May 2025. The use of plastic has been reduced to the minimum level required for maintaining functionality and durability, resulting in a 59% reduction* compared to conventional products, with recycled resin also used for some parts. During disposal, the paper case and plastic sections can be easily pulled apart by hand. With a range of designs and textures unique to paper cases, they feature watercolor designs that cannot be achieved with plastic materials—they incorporate ideas that have been designed to match the day-to-day lives of users like other accessories, making them fun to use.

-

*

Compared to our conventional “Roller Kes’pon Stick.”

“Kaite Memo” Eco-friendly Magnetic Memo Pads—Easy-to-read and write on in the palm of your hand

The “Kaite Memo” clean writing and erasable memo pad of the “Kaite” series was released in December 2024, made of a magnetic sheet and special pen giving users a natural writing feel as writing on paper with a pencil. With no consumable items like paper, ink or batteries, it is an economical and eco-friendly product enabling repeated writing and erasing. “Kaite Memo” provides greater contrast of written characters compared to past products, and is sturdy enough to write while standing, with a smooth writing experience. Photos can be taken of any notes to keep with the free dedicated app, which can then be saved and shared.

-

Investigating and reducing hazardous chemical substances

We will switch from raw materials which contain chemical substances that may cause water, air, or soil contamination, or may have a worrying impact on the human body, to safer raw materials. We strive for appropriate disclosure of information regarding chemical substances to our employees and customers, and provide safe and reliable products that pay due consideration to the global environment.

-

Thoroughly control chemical substances and hazardous substances in products

Exhaust processing and emissions restrictions of VOCs (volatile organic compounds)

At the Bien Hoa Plant of PLUS VIETNAM INDUSTRIAL CO., LTD. (Dong Nai Province, Vietnam) and the Shanghai Plant of PLUS Stationery Shanghai Co., Ltd (Shanghai, China), we have deployed VOC exhaust processing systems that use activated charcoal filters to remove VOCs*1, which are a source of air pollution. The Bien Hoa Plant also checks the VOC content not contained in the air in the pad printing*2 section.

Also, the Shantou Plant of Shantou PLUS Instruments Co., Ltd (Guangdong Province, China) makes considerations with regards to environmental pollution and safety of plant workers by restricting VOC emissions by utilizing a proprietary development method using water-based paints, powder coating, and water-based adhesives in some white boards.

-

*1

Abbreviation of “Volatile Organic Compounds” The Shantou Plant does not use VOCs in water-based paints, powder coating, or water-based adhesives (with the exception of some products).

-

*2

A printing method in which silicon rubber pads containing ink are pressed, like a stamp, onto products

Compliance with laws and regulations, and prevention of pollution

In compliance with laws and regulations concerning the environment as well as with other requirements to which the PLUS Group has agreed, we establish our own standards where necessary and make efforts to prevent environmental pollution.

Training for preventing pollution Primary contents of activities Mock training for plant drainage emergency (Maebashi Plant) - Once a year, we hold mock emergency response training. In this training, we assume a case of non-compliant discharge of plant waste water into the Kanzawa River (class A river).

- Normal waste water produced through production processes and waste liquids created during updates are appropriately processed according to the standards stipulated in laws and regulations, so we regularly monitor and measure them based on the management procedures and implementation responsibilities that we have established.

Management of poisonous materials, deleterious substances and toxic materials (Maebashi Plant) - We appoint a safety supervisor responsible for verifying safety management, to ensure proper handling and storage warehouse management.

- We identify potential risks by conducting regular inspections, while ensuring that appropriate storage conditions are maintained at storage warehouses.

Management of organic solvents and specified chemical substances (Maebashi Plant) - We identify the hazards and toxicity of chemical substances by ensuring an understanding of the chemical substances being handled and developing risk assessments.

- We conduct special medical check-ups twice a year for workers handling organic solvents and specific chemical substances, for the health management of workers.

Mock training to respond to leakage of chemical products (PLUS VIETNAM INDUSTRIALCO., LTD.) - Once a year, we hold training for dealing with leakage of chemical products along with in-house fire drills.

- Employees receive training on the safe use and storage of chemical products, collection in the event of a leakage, and post-event environmental recovery. Every month, we perform an audit to check for compliance with environmental laws and regulations.

-

-

Call attention to safety when using products

Provision of information concerning hazards and toxicity

The PLUS CORPORATION has created a support page on our website to share information that allows customers to use the products of all our businesses safely. The support page includes a contact center, FAQ, instruction manuals, and assembly instructions. It also includes Safety Data Sheets (SDS) that caution customers about hazards to human health and the environment, product properties that could cause fire or explosion, and measures to take in the event of an emergency. It contains information about the chemical properties of products for which we receive many inquiries, and customers can download these at any time.

It is necessary to know the volume of CO2 emissions before reducing them. We first calculated and disclosed the volume of emissions from our plants in 2020. Since then, we continue to expand the scope of our investigations. Henceforward we must enter the reduction phase, so our company has carried out organizational restructuring for that purpose.

Going forward, we are also looking at reductions and disclosure of information on the part of the entire Group. We will work on both product development and sustainability implementation to fulfill our responsibilities as a member of society, and to become a Group of which the next generation of young people will say, "I want to work for a company like that."

Sustainability implementation, CSR Division, Stationery Company